Top Guidelines Of Mhs - Material Handling Supply Inc.

Top Guidelines Of Mhs - Material Handling Supply Inc.

Blog Article

Top Guidelines Of Mhs - Material Handling Supply Inc.

Table of ContentsThe Best Guide To Mhs - Material Handling Supply Inc.The Only Guide to Mhs - Material Handling Supply Inc.Little Known Facts About Mhs - Material Handling Supply Inc..Get This Report on Mhs - Material Handling Supply Inc.Excitement About Mhs - Material Handling Supply Inc.The Greatest Guide To Mhs - Material Handling Supply Inc.

This line is called the line of activity. forklift rental near me. If all-time low of this line goes outside of the stability triangle due to the fact that a lots is as well heavy or expensive, or because the forklift is out a degree surface it will tip over. An upright line expanding from the facility of gravity of the vehicle-load combination should stay inside the security triangle to avoid the forklift from tippingThis security triangular is made by linking the two front wheels and the pivot factor of the back axle. The other idea to understand is the forklifts facility of gravity. Notification that the front and back sides of the security triangular are high-lighted. When unloaded, the forklifts facility of gravity is best concerning right here.

Larger loads shift the center of mass forward even additionally. Raising the lots also shifts the center of mass onward. In order to avoid the lift from tipping, the consolidated facility of gravity of the lots and the lift should remain inside the stability triangular (at ground degree) in any way times.

Mhs - Material Handling Supply Inc. Fundamentals Explained

If you have a balanced lots, the load is unlikely to affect the side-to-side center of mass. https://www.domestika.org/en/tannergraves30677. But if you drive on a sloped surface area, your center of gravity could pass beyond the stability triangular and the lift could tip. Every forklift has a recognition plate that notes essential details about the truck

To be certain that the center of mass of your forklift stays inside the security triangular, do not attempt to raise anything much heavier than the identification plate enables. Regardless of how active you are, you must check your forklift before using it. If you do find something that could impact the safety of the lorry you must report it quickly.

Bear in mind, the operator is liable for the secure procedure of the forklift. If the forklift is made use of around the clock, evaluate it either prior to each shift or after each change.

The smart Trick of Mhs - Material Handling Supply Inc. That Nobody is Discussing

It is completed in two parts: the walk-around inspection, and, the seated evaluation. OSHA does not require documents of a day-to-day assessment. However it's a good concept to have a checklist to see to it you do not miss any steps. These lists can likewise be conserved as a component of the upkeep document.

Inspect the condition of the tires. If the forklift is an outside forklift with pneumatically-driven tires, examine the air pressure and search for excessive endure the tires. A tire with reduced air pressure can cause the lift to tip when a load is raised. So could a tire failing.

Excitement About Mhs - Material Handling Supply Inc.

Examine the engine for any kind of indicators of wear, loosened connections, or leaks. Look for fractures or deformities in the forks, backrest, mast, and above guard. Inspect the recognition plate to make certain it is intact and readable.

Start the engine. Always start the engine while seated in the driver's positionnever while standing along with the forklift. Check all determines and advising lights, and the battery or gas degree. Obtain aware of the controls. Lift and decrease the forks, and tilt the pole. Make certain that whatever functions smoothly and is clearly classified.

The Main Principles Of Mhs - Material Handling Supply Inc.

You'll need to appear the horn at crossways, and wherever vision is blocked. Check the brakes by dispiriting the brake pedal. There must be some resistance. Establish and test the hand brake. Check the guiding. A whole lot of play or tough steering will certainly decrease your control. Relocate the forklift onward a few feet.

Leakages could from this source suggest a hydraulic trouble, and liquids left on the flooring are a sliding hazard. Additionally seek triggers or flames coming out of the exhaust system. Listen for any uncommon audios. If you find anything wrong with the forklift throughout the walk-around or seated assessment, do not run it until it has actually been fixed.

Mhs - Material Handling Supply Inc. Fundamentals Explained

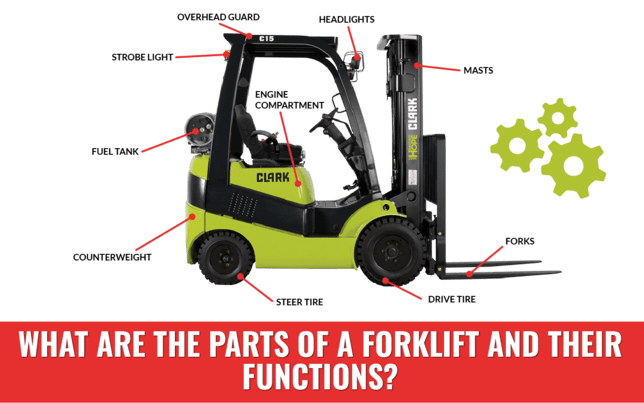

Forklifts have numerous relocating parts and pieces that permit the forklift to run properly. Recognizing the terms of the parts and makeup of a forklift is essential for effective interaction with others while on duty - https://visual.ly/users/tannergraves30677/portfolio. Below are some of the essential features and components that comprise the composition of a forklift vehicle

For the majority of forklifts, the pole is created toward the front of a forklift and directly in the forklift driver's line of sight. Forklift poles feature different areas that raise or reduced the forklift carriage in addition to the forks. These include:: 2 pole stages: 3 pole phases: 4 mast sections When picking a forklift, it is essential to acquaint yourself with the different attributes and terms of a forklift mast: the pole's lift elevation, the complimentary lift height and the extensive elevation and the reduced elevation.

Report this page